Fanuc Robot Encoder Cable SR-RCC-G8ES-A07

Product Description

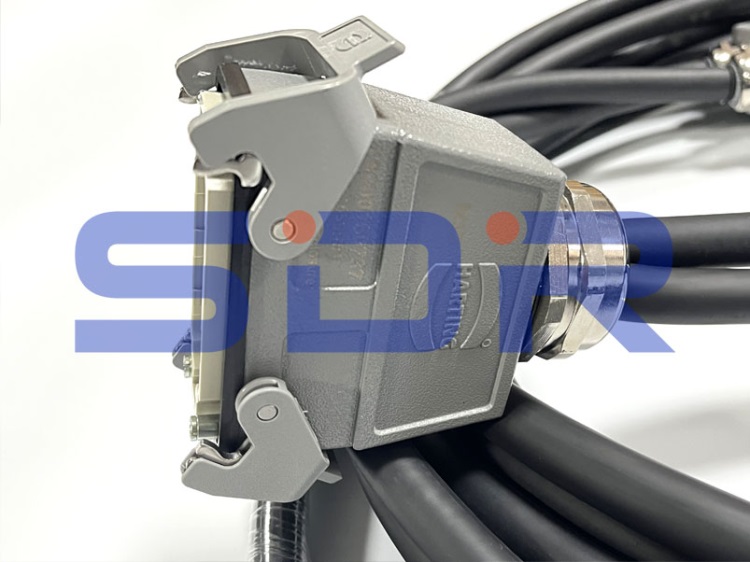

Fanuc Robot Encoder Cable is a cable product specially designed for Fanuc Robot Encoder. It is made of high-quality materials, has the characteristics of wear resistance and high temperature resistance, has standardized connection interfaces, is easy to operate, and is widely used in various robot systems. It also has a number of safety protection measures, such as waterproof, dustproof, anti-electromagnetic interference, etc., which can provide a stable and reliable connection for the robot encoder to ensure the normal operation of the robot system. Fanuc Robot Encoder Cable is a high-performance, high-reliability product that is an integral part of a robot system.

Product Specification

| Brand: | Fanuc |

| Cable Model No.: | SR-RCC-G8ES-A07 |

| Length: | 7M |

| Material: | PUR sheath, Bare Copper Wire |

| Applicable Model: | R-30ib Mate Cabinet |

| Assembling: | Moving Towline Assembled or Normal Fixed Assembling |

1.Data Transmission:The primary function of the encoder cable is to transmit position and speed data from the encoders to the robot’s control system. This data is essential for the robot’s precise movement and positioning.

2.Signal Integrity:The cable ensures the integrity of the signals being transmitted, minimizing data loss or interference that could affect the robot’s performance.

3.Power Supply:In addition to data transmission, the encoder cable may also provide power to the encoders, enabling them to function correctly.

4.Error Detection:The cable is designed to help detect and prevent errors in signal transmission, contributing to the overall reliability of the robot's operation.

1.High-Precision Design:Encoder cables are designed to support high-precision applications, ensuring accurate data transmission and reliable performance.

2.Shielding:Many encoder cables feature shielding to protect against electromagnetic interference (EMI) and radio frequency interference (RFI), which can disrupt signal transmission.

3.Durability:These cables are built to withstand the harsh conditions often found in industrial environments, including temperature extremes, abrasion, and mechanical stress.

4.Connector Types:Fanuc robot encoder cables come with various connectors, such as circular or rectangular connectors, depending on the robot model and application requirements.

5.Flexible Construction:The cables are designed to be flexible, allowing for smooth movement of the robot's joints without stressing the cable.

1.Preparation:Before installation, ensure that the robot is powered off and disconnected from its power source. This step is crucial for safety and to prevent damage to the components.

2.Routing:Route the encoder cable through the robot’s cable management system, avoiding sharp bends or pinch points that could damage the cable.

3.Connecting:Attach the encoder cable to the encoders and the robot’s controller using the appropriate connectors. Ensure that the connections are secure and correctly aligned.

4.Testing:After installation, power on the robot and test the encoder system to verify that the cable is transmitting data accurately and that the robot operates as expected.

FAQ:

What is the main function of Fanuc robot encoder cable?

The main function of a Fanuc robot encoder cable is to transmit the position and velocity data collected by the encoder to the robot's control system for precise robot motion and positioning.

How does the encoder cable ensure signal integrity?

Encoder cables ensure signal integrity and stability by utilizing a shielded design to protect the signal transmission from electromagnetic interference (EMI) and radio frequency interference (RFI).

What do I need to be aware of when installing Fanuc robot encoder cables?

Installation involves ensuring that the robot is powered off, avoiding sharp bends or crushing of the cable, properly connecting the cable to the encoder and controller, and testing the cable for signal transmission.

What are the common connector types for Fanuc robot encoder cables?

Common connector types include circular and rectangular connectors, depending on the robot model and application requirements.

How do I maintain my Fanuc Robotics encoder cable?

Regularly inspect cables for wear, damage, or loose connections, keep cables and connectors clean, promptly replace damaged cables, and monitor the control system for encoder-related error codes.

How durable are the encoder cables?

Encoder cables are designed for high durability and can withstand temperature extremes, abrasion and mechanical stress in industrial environments, but excessive pulling and bending should still be avoided.

How do I handle a faulty Fanuc robot encoder cable?

When dealing with a fault, first check the cable for obvious damage or looseness, reconnect or replace the cable, use the error codes in the control system for troubleshooting, and seek professional technical support if necessary.

Why do I need to carry out regular checks on the encoder cable?

Regular inspections can identify potential problems with the cable, such as wear, damage or loose connections, and dealing with these problems in a timely manner can prevent degradation of robot performance or downtime.

Do encoder cables require special cleaning methods?

Encoder cables should be cleaned with a soft cloth and a mild detergent. Avoid using strong acids, alkalis, or caustic cleaners that may damage the cable.

What are the precautions for replacing encoder cables on Fanuc robots?

Replacement should ensure that the new cable is compatible with the robot and installed according to the manufacturer's specifications and requirements, avoiding the use of unofficially recognized cables that may lead to compatibility issues or performance degradation.