Built to withstand the demands of industrial environments, Robot Cables are engineered for durability, resistance to mechanical stress, and protection against factors like temperature fluctuations and electromagnetic interference. Available in different types, lengths, and configurations, Robot Cables cater to various robotic applications, supporting automation processes in manufacturing, assembly, and more. Their role in maintaining signal integrity and providing consistent power supply is crucial for the reliable operation and performance of robotic systems.

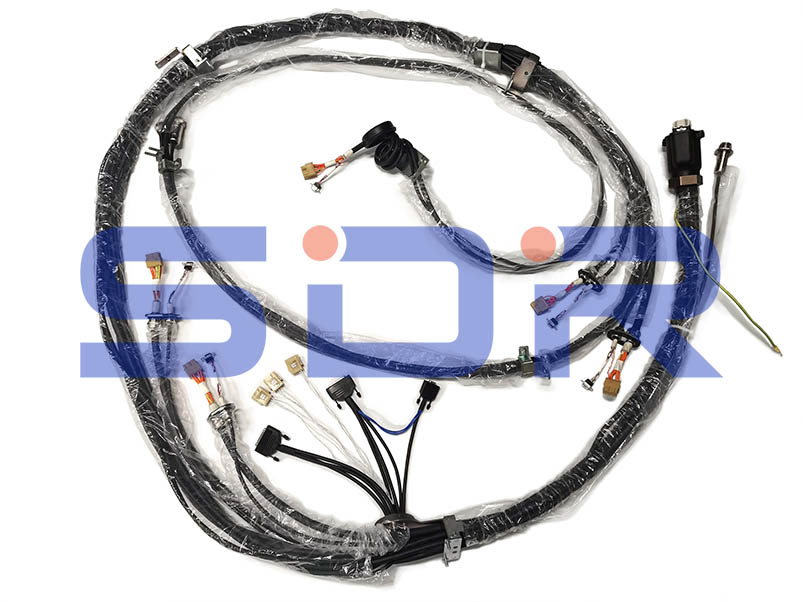

ABB 6 Axis Robot ABB Robot Cables for Sale

Product Description

ABB Robot Cables are made from high-quality materials that are resistant to wear and tear, making them highly durable. They are designed to withstand harsh environments, including exposure to chemicals, oil, and other substances that may damage the cable. Manipulator Harn. ax 1-6 has the advantages of high flexibility, durability, reliable signal transmission, safety, and easy installation.

Product Specifications

| Brand: | ABB |

| Sheath Material: | Environment-friendly PVC |

| Core Material: | Bare Copper Wire |

| Application Model: | ABB 6640/6650/6600/6700 |

| Cable Model No. | 3HAC024386-001 3HAC024385-001 |

| Connectors: | ABB Original Connects |

Fanuc Robot Cables Manufacturer:

Fanuc robot cables are specialized wiring solutions designed to ensure seamless communication and power transmission within Fanuc industrial robots. These cables are engineered to provide reliable connectivity between the robot's control unit, motors, sensors, and peripherals. With durability in mind, Fanuc robot cables are built to withstand harsh industrial environments, offering resistance to mechanical stress, temperature variations, and electromagnetic interference.

Fanuc Ee Cable Price:

Fanuc EE cables are specialized components designed for Fanuc robots. They enable data transmission and power supply, critical for seamless robotic operations. For specific pricing, it's best to contact authorized Fanuc dealers or distributors.

Igus Robot Cables Use:

Igus robot cables are specialized cables designed for industrial robots and automation systems. They are used for transmitting data, signals, and power, supporting various robot functions such as motion, control, and sensing applications. These cables are known for the ir abrasion resistance, corrosion resistance, and ability to withstand harsh environmental conditions. They find applications in industries like manufacturing, logistics, and healthcare, ensuring reliable connections and efficient automation operations.

Teach Pendant Cable Maintenance:

Proper maintenance of a teach pendant cable is essential for the optimal performance and longevity of your robotic system. Regularly inspect the cable for signs of wear, such as fraying or cuts, paying special attention to connectors for any damage or looseness. Keep the cable clean by gently wiping it with a dry cloth to remove dust and debris.

Robotic Flexible Cables Performance:

Robotic flexible cables are constructed with materials and designs that allow them to bend, twist, and move in multiple directions without compromising signal integrity or electrical performance. They are commonly used in robotic arms, industrial automation, and other robotic systems where constant motion is a critical factor. These cables provide reliable connectivity for power, data transmission, and communication within robotic systems, enabling seamless and efficient operation.

Lego Nxt Cable:

LEGO NXT cables are essential components for the LEGO Mindstorms NXT robotics system. These cables facilitate communication and power transmission between various sensors, motors, and the NXT intelligent brick.Designed for durability and flexibility, these cables withstand the movement and manipulation required in robotic creations. They come in different lengths and types to suit specific applications, offering versatile connectivity options.

Vex V5 Smart Cables:

VEX V5 Smart Cables come in various lengths and types, accommodating different designs and configurations. Their compatibility with the VEX ecosystem guarantees seamless integration into a wide range of applications, from small-scale classroom projects to advanced competition robots.To maintain their performance, users should regularly inspect cables for wear, bends, or loose connectors. Careful handling, proper storage, and avoiding excessive bending contribute to their longevity.

Robot Wires Maintenance Method:

Maintaining robot wires is crucial for the efficient operation of robotic systems. Follow these steps to ensure their longevity:

1. Regular Inspection: Routinely examine wires for signs of wear, such as fraying or exposed insulation. Check connectors for damage or looseness.

2. Cleanliness: Keep wires clean by gently wiping them with a dry cloth to remove dust and debris. Avoid using abrasive materials that could damage the insulation.

3. Bending Prevention: Minimize excessive bending, twisting, or pulling of wires to prevent strain on internal conductors. Use proper cable management to route wires safely.

4. Storage: When not in use, coil wires loosely and store them in a cool, dry place to prevent exposure to moisture or extreme temperatures.

5. Connector Care: Attach and detach connectors with care to prevent bending or breaking pins. Ensure connectors are securely fastened.

6. Chemical Avoidance: Keep wires away from chemicals, oils, or solvents that could degrade insulation or conductors.

7. Weight Management: Prevent heavy objects from resting on wires, which can damage the internal conductors.

8. Prompt Repairs: Address any visible damage promptly. Replace damaged wires or connectors to prevent further issues.

9. Professional Maintenance: Schedule regular maintenance checks by qualified technicians to ensure wire integrity and functionality.

10. Documentation: Maintain records of maintenance activities, inspections, and any repairs performed on the wires.

Following these maintenance practices will extend the lifespan of your robot wires, ensuring reliable performance in your robotic system.

FAQ:

What are Robot Cables?

Robot Cables are cables specifically designed for use in robotic systems to transmit power and signals and are resistant to high loads, bending, abrasion and interference.

What are the main functions of Robot Cables?

The main functions include power transmission, signal transmission, data transmission, and ensuring stable and efficient communication between the various components of the robot.

What materials are Robot Cables typically made of?

Robot Cables are typically made of highly flexible conductors (e.g. copper) and insulating materials (e.g. polyurethane, polyethylene) that are resistant to abrasion, high temperatures, and chemicals to ensure their reliability in robotic applications.

What applications are Robot Cables used for?

These cables are widely used in industrial robots, collaborative robots, automated production lines, robotic arms, etc. to ensure stable power and signal transmission in robotic systems.

How to choose the right Robot Cables?

Selection should take into account the cable's flexibility, temperature resistance, abrasion resistance, shielding, as well as current and voltage specifications to match the needs of the particular robot application.

How are Robot Cables different from regular cables?

Robot Cables are designed to be more flexible and durable, withstanding frequent bending, twisting, and abrasion that ordinary cables typically do not.

How do I install Robot Cables?

When installing Robot Cables, make sure that the cables are used within the bend radius to avoid overstretching or twisting. Use appropriate fixings as required and ensure that the cable connections are stable and secure.

Do Robot Cables require regular maintenance?

Yes. Periodically check the appearance of the cables to ensure there is no wear, tear or deterioration. Depending on usage, cables may need to be replaced to keep the Robot System operating properly.

How do Robot Cables perform in high temperature environments?

Many Robot Cables are designed to withstand high temperatures and are capable of stable operation in high temperature environments. High temperature resistance should be considered when selecting cables for different operating environments.

Can Robot Cables be customized?

Yes, Robot Cables can be customized to meet specific needs, including different lengths, gauges, insulation materials, and shielding methods to meet the requirements of a particular robot system.