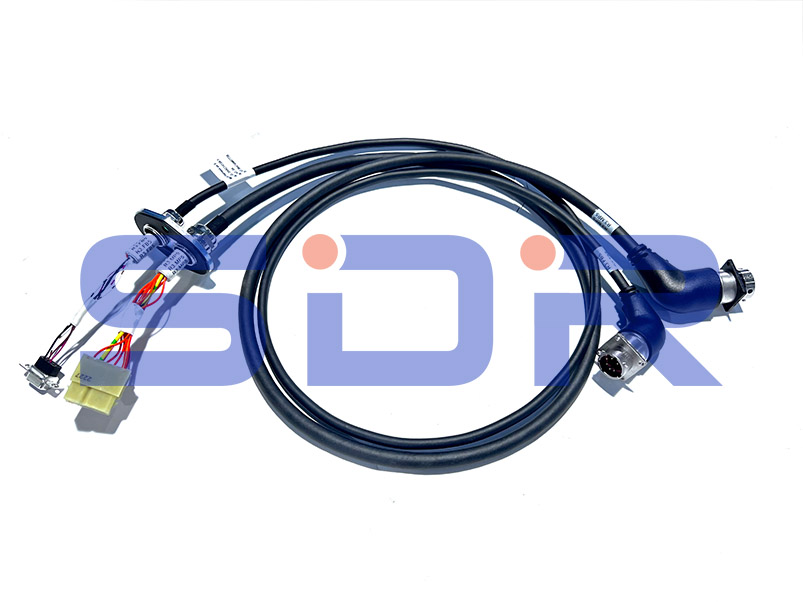

ABB robot body cables serve as the bridge that enables seamless communication, efficient power delivery, and expanded capabilities for the robotic system.These wires carry electrical power from a power source to various components within the robot, such as motors, actuators, and sensors. They need to handle different voltage and current levels, depending on the specific requirements of the robot.Signal cables are used to transmit low-voltage electrical signals for control, feedback, and communication between different parts of the robot. Examples include Encoder Cables for position feedback and sensor cables for environmental feedback.

PRODUCT SPECIFICATION:

Model Number: | 3HAC14139-1 | Inner Material: | TPE |

Brand: | ABB ROBOT | Application: | On robot body including PW and En cables |

Robot No.: | ABB 6640 | Installation: | Fixed Installation |

Cabinet No.: | ABB 6640 | Temperature: | -10℃ ~ + 80℃ |

Jacket Material: | PVC | Working Voltage: | 500V |

Flame-retardant: | VW-1(UL) | Length: | Original length or as customed (0~10m) |

Water-pfoof grade: | IP20 | Certificate: | UL certification,CE compliant,RoHS compliant |

Quality Assurance: | 1year(can be used for 3years) | Anti-interference: | can meet the anti-interference requirements of use |

Voltage Rating: Suitable for high-voltage applications to ensure reliable power delivery.

Temperature Range: Typically operates within a wide temperature range to accommodate different working conditions.

Cable Length: Available in various lengths to suit different installation requirements.

Connector Types: Equipped with standard connectors compatible with ABB 6640 robots, ensuring easy and secure connections.

Welding

Resistance Welding: Ensures consistent power delivery for precise welding operations.

Arc Welding: Provides stable power and feedback signals for high-quality welds.

Material Handling

Pick and Place: Enables accurate positioning and handling of materials.

Palletizing: Supports efficient stacking and organization of products.

Assembly

Component Assembly: Ensures precise movements for accurate assembly of parts.

Screwing and Fastening: Provides stable power for tools used in fastening applications.

Painting and Coating

Surface Coating: Ensures smooth and even application of paints and coatings.

Detailing: Allows for precise and intricate painting tasks.

Regular Inspection: Regularly check the cables for signs of wear, damage, or corrosion to ensure optimal performance and safety.

Proper Installation: Ensure cables are correctly installed and routed to avoid sharp bends and excessive tension, which can lead to premature failure.

Safety Standards: Comply with industry safety standards and guidelines for electrical installations to prevent accidents and ensure the longevity of the cables.

About Us

Super Dragon Electric Technology(DongGuan) Co.,LTD is a manufacturing enterprise dedicated to the production and sales of robot wire harness products. If you are interested in our Robot Cables, feel free to enquiry at any time.

What is the ABB 6640 robot body cable PW+EN?

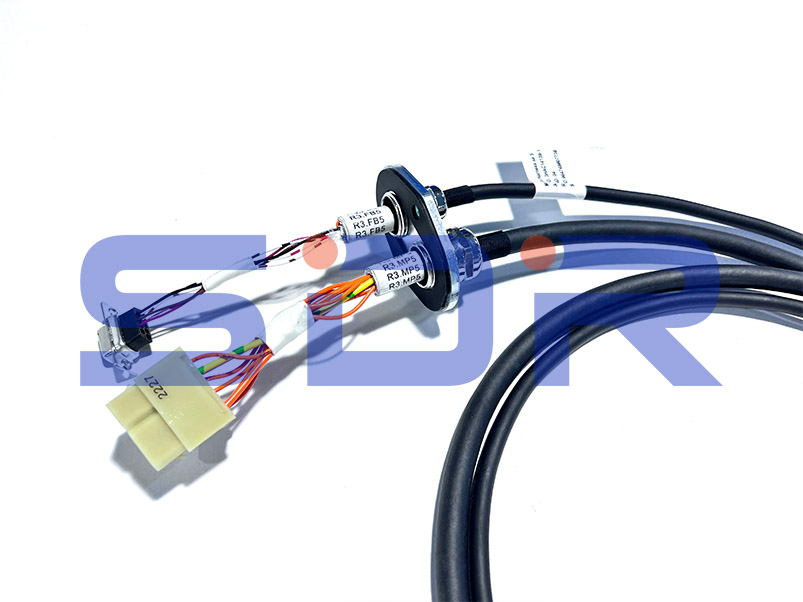

The ABB 6640 robot body cable PW+EN is a cable assembly used to transmit power and encoder signals to ensure power supply and precise position feedback to all robot components.

FAQ:

What do PW and EN stand for?

PW stands for Power Cables, which transmit power, and EN stands for Encoder Cables, which transmit encoder feedback signals.

What is the main function of these cables?

The power cables (PW) are responsible for transmitting power from the control unit to the motors and components of the robot, while the encoder cables (EN) transmit the feedback signals to ensure precise monitoring and control of the robot's movements.

What are the main materials that make up the ABB 6640 robot body cable?

The cables usually consist of a high quality copper conductor and a robust insulation with a shielding layer to protect against electromagnetic interference (EMI).

What are the characteristics of these cables?

Durability: Can withstand constant bending and twisting.

Heat Resistance: Withstands high operating temperatures.

Shielding: Prevents EMI and ensures integrity of signal transmission.

What are the typical applications for these cables?

Welding: Ensure stable power supply and accurate feedback signals during welding operations.

Material Handling: Ensure precise positioning during picking, stacking, etc.

Assembly: Providing stable power and precise control in operations such as parts assembly and screw fixing.

Painting: Ensures uniform application of paints and coatings.

What are the technical specifications of the cables?

Voltage Rating: Suitable for high voltage applications to ensure reliable power transmission.

Temperature range: Able to operate over a wide range of temperatures to suit different operating conditions.

Length: Available in various lengths to meet different installation requirements.

Connector type: Fitted with standard connectors compatible with ABB 6640 robots, ensuring a secure and reliable connection.

How do I maintain these cables?

Regular inspection: Check the cables regularly for signs of wear, damage or corrosion.

Install correctly: Ensure that the cables are installed correctly, avoiding sharp bends and overstretching.

Follow safety standards: Follow industry safety standards and guidelines for electrical installations.

How do these cables enhance the performance of the robot?

By ensuring a stable power supply and accurate feedback signals, these cables support efficient and precise operation of the robot in a variety of applications, enhancing overall performance and reliability.

What is the future direction of these cables?

More environmentally friendly: Use more recycled and bio-based materials.

Improved performance: Increased heat, chemical and abrasion resistance.

Design capabilities: Add new textures, patterns and customization options.

Smart Integration: Incorporating smart technologies, such as embedded sensors, to monitor structural health.