SERVO Motor Cables are the connective tissue of precision motion control systems. This article dives into the world of SERVO motor cables, exploring their significance, composition, and their crucial role in powering seamless motion in a variety of applications.In the realm of robotics, automation, and industrial machinery, SERVO motors stand as champions of precision and control. Supporting these motors are SERVO motor Cables, essential conduits responsible for transmitting power and data between the control system and the motor, ensuring accurate and efficient motion.

SERVO motors are designed for accuracy, speed, and reliability. The performance of these motors hinges on the quality of the Cables that power them. SERVO motor cables enable the bidirectional flow of information, facilitating real-time feedback and adjustments that ensure precise positioning and controlled movement.

Composition and Features

Shielding: SERVO motor cables often come equipped with shielding to prevent electromagnetic interference. This shielding maintains signal integrity and protects against external noise.

High Flexibility: Motion control systems demand flexibility to accommodate the dynamic movements of SERVO motors. These cables are designed to bend and twist without compromising performance.

High Temperature Rating: SERVO motor cables are often exposed to heat generated by motors and machinery. Their high-temperature resistance ensures stable performance even in demanding environments.

Durable Jacketing: A robust outer jacket protects the cables from physical damage, abrasion, and exposure to oils, chemicals, and other industrial agents.

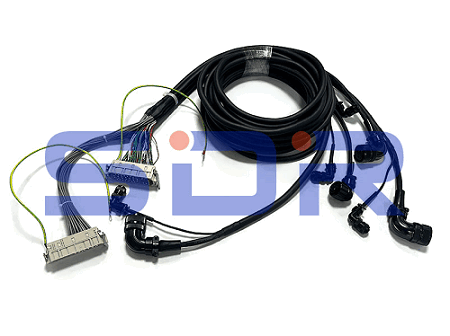

Connector Varieties: Different SERVO motor models and systems require specific connectors. Matching connectors ensure secure connections and reliable data transfer.

SERVO motor cables are the backbone of automated production lines, robotics, CNC machinery, and more, ensuring precise and repeatable movements.In robotic systems, SERVO motor cables enable the coordinated and accurate movement of robot arms, enhancing their agility and functionality.Medical equipment such as surgical robots and imaging systems rely on SERVO motor cables for precise and controlled motion during delicate procedures.In industries where reliability and precision are paramount, SERVO motor cables power critical components like control surfaces in aircraft and precision machinery in automotive manufacturing.

SERVO motor cables are the unsung heroes of motion control, enabling the precision and reliability demanded by industries ranging from manufacturing to healthcare. Understanding their role, features, and proper maintenance is essential for unlocking the full potential of SERVO motor systems. Whether in factories, medical facilities, or beyond, SERVO motor cables play a crucial role in powering the dynamic and precise movements that define modern automation and innovation.