In the field of modern industrial automation, SERVO motors are vital equipment, and SERVO Motor Cable plays a vital role as a key component connecting motors and controllers. This article will delve into the definition, structure, working principle, application fields, selection and maintenance of SERVO Motor Cable, aiming to help readers fully understand this key component.

1. Definition of SERVO Motor Cable

SERVO Motor Cable is a cable used to connect SERVO motors and controllers. It transmits power, signals and data, allowing the control system to accurately control the movement and position of the motor.

2. Structure of SERVO Motor Cable

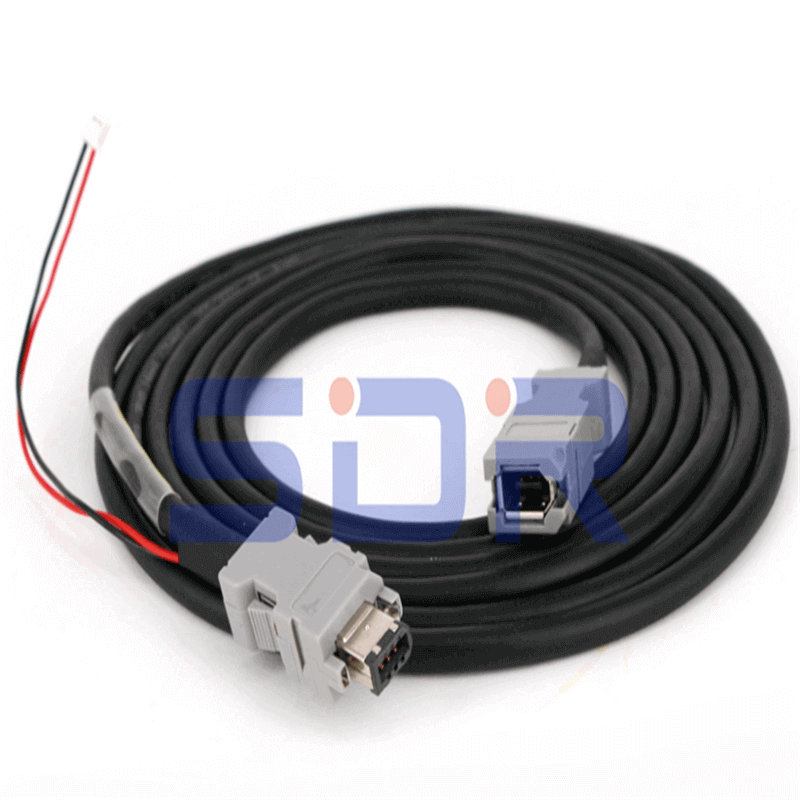

Typically, a SERVO Motor Cable consists of multiple parts, including:

Conductor: Typically a stranded copper wire used to carry power and signals.

Insulation: Covered around a conductor to isolate the conductor and prevent short circuits in the circuit.

Jacket: Covers the outside of the insulation to provide additional protection and abrasion resistance.

Connectors: used to connect cables to motors and controllers.

3. Working principle of SERVO Motor Cable

The working principle of SERVO Motor Cable involves power transmission and signal transmission. Power transmission occurs through conductors, and a controller controls the movement of the motor by supplying power to it. Signal transmission is achieved through signal lines in conductors, and the controller sends instructions and feedback signals to the motor to achieve precise motion control.

4. Application areas of SERVO Motor Cable

SERVO Motor Cable is widely used in various industrial automation fields, including:

Machine tool processing: used for equipment such as CNC machine tools and machining centers.

Automotive manufacturing: used in robotics and automated production lines.

Medical equipment: used in imaging equipment, surgical robots, etc.

Packaging machinery: used in packaging production lines and automatic packaging machines, etc.

5. SERVO Motor Cable selection and maintenance

Choosing the right SERVO Motor Cable is crucial and you need to consider the following factors:

voltage and current requirements.

transmission distance and environmental conditions.

Anti-tampering and wear resistance requirements.

Connector types and interface standards.

For the maintenance of SERVO Motor Cable, you usually need to pay attention to the following matters:

Check the appearance of the cable regularly to ensure there is no damage or wear.

Avoid excessive bending and stretching of Cables.

Clean cable connectors regularly to ensure good contact performance.

SERVO Motor Cable, as an important component connecting SERVO motors and controllers, plays a key role in the field of industrial automation. Through in-depth knowledge of its definition, structure, working principle, application areas, selection and maintenance, we can better understand and apply this key component and improve the performance and reliability of automation systems.

FAQ:

What is SERVO Motor Cable?

SERVO Motor Cable is a cable used to connect SERVO motors and controllers. It is used to transmit power, signals and data to achieve precise control of motor movement and position.

What are the main components of a SERVO Motor Cable?

The main components include conductors, insulation, jackets and connectors.

What are the main functions of SERVO Motor Cable?

Its main function is to transmit power and signals so that the control system can accurately control the movement and position of the SERVO motor.

In what areas is SERVO Motor Cable widely used?

SERVO Motor Cable is widely used in industrial automation fields, including machine tool processing, automobile manufacturing, medical equipment, and packaging machinery.

What factors should be considered when choosing SERVO Motor Cable?

When selecting SERVO Motor Cable, you need to consider factors such as voltage and current requirements, transmission distance and environmental conditions, anti-interference and wear resistance requirements, as well as connector type and interface standards.

How does the SERVO Motor Cable work?

Its working principle involves power transmission and signal transmission. Power is transmitted through conductors to control motor movement, and instructions and feedback signals are transmitted through signal lines to achieve precise control.

What should I pay attention to when maintaining SERVO Motor Cable?

During maintenance, it is necessary to regularly check the appearance of the cable to ensure that there is no damage or wear; avoid excessive bending and stretching of the cable; regularly clean the cable connector to ensure good contact performance.

What directly affects the performance of SERVO Motor Cable?

The performance of SERVO Motor Cable directly affects the operational stability, accuracy and reliability of the automation system, so choosing the right cable is crucial.