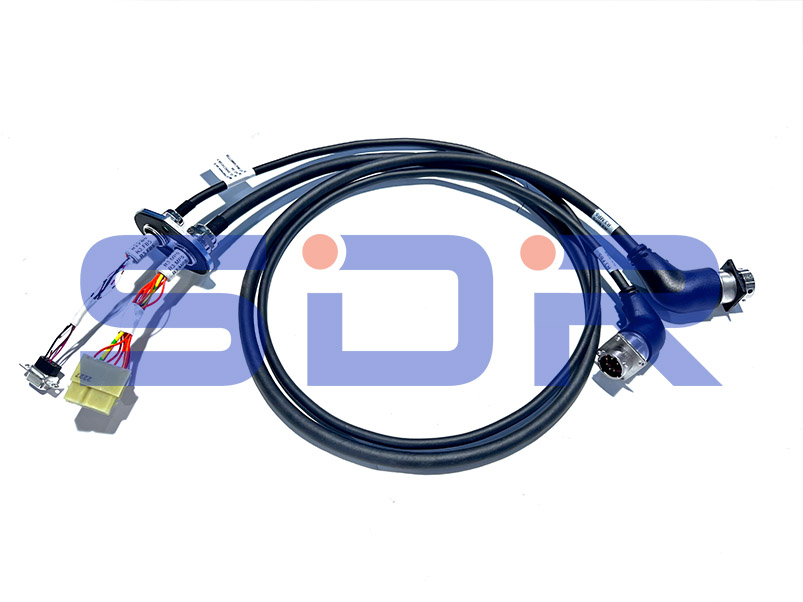

The ABB IRB 6640 is a robust and versatile industrial robot widely used for various applications, including welding, material handling, assembly, and more. Central to the robot's performance and reliability are its body cables, specifically the Power (PW) and Encoder (EN) cables. These cables ensure that the robot receives the necessary power and precise control signals, making them essential components in the overall system.

POWER CABLEs (PW)

Durability: Designed to withstand continuous flexing and twisting.

Heat Resistance: Capable of withstanding high operating temperatures.

Shielding: Includes shielding to protect against electromagnetic interference (EMI).

Purpose: To transmit electrical power from the control unit to the robot's motors and other components.

Construction: Comprised of high-quality copper conductors with robust insulation to handle high current loads and endure harsh industrial environments.

Features:

Encoder Cables (EN)

Signal Integrity: Ensures high-quality, noise-free signal transmission.

Flexibility: Suitable for dynamic applications with constant movement.

Robustness: Resistant to wear and tear in demanding industrial environments.

Purpose: To transmit feedback signals from the robot's encoders to the control system, enabling precise monitoring of the robot's position and movements.

Construction: Made with precision-twisted pairs of conductors and high-quality shielding to ensure accurate signal transmission.

Features:

Voltage Rating: Designed to handle high-voltage applications, ensuring reliable power delivery.

Temperature Range: Operates within a wide temperature range to accommodate various working conditions.

Cable Length: Available in multiple lengths to suit different installation requirements.

Connector Types: Equipped with standard connectors compatible with ABB 6640 robots, ensuring easy and secure connections.

Reliability and Precision: The PW and EN cables are crucial for maintaining the robot's operational reliability and precision, as they ensure consistent power supply and accurate position feedback.

Cost-Effectiveness: By providing reliable performance and reducing downtime, these cables contribute to the overall cost-effectiveness of the robotic system.

Flexibility: The design and construction of these cables allow them to be used in a variety of industrial environments, from high-temperature settings to areas with significant electromagnetic interference.

Welding

Resistance Welding: Ensures consistent power delivery for precise welding operations.

Arc Welding: Provides stable power and feedback signals for high-quality welds.

Material Handling

Pick and Place: Enables accurate positioning and handling of materials.

Palletizing: Supports efficient stacking and organization of products.

Assembly

Component Assembly: Ensures precise movements for accurate assembly of parts.

Screwing and Fastening: Provides stable power for tools used in fastening applications.

Painting and Coating

Surface Coating: Ensures smooth and even application of paints and coatings.

Detailing: Allows for precise and intricate painting tasks.

Regular Inspection: Regularly check the cables for signs of wear, damage, or corrosion to ensure optimal performance and safety.

Proper Installation: Ensure cables are correctly installed and routed to avoid sharp bends and excessive tension, which can lead to premature failure.

Compliance with Standards: Follow industry safety standards and guidelines for electrical installations to prevent accidents and ensure the longevity of the cables.

The future of industrial robotics and their components, like the ABB 6640 Robot Body Cable PW+EN, looks promising with ongoing advancements in materials and technology. Potential developments include:

Enhanced Eco-Friendliness: Increased use of recycled and bio-based materials.

Improved Performance: Greater resistance to heat, chemicals, and wear.

Advanced Design Capabilities: New textures, patterns, and customizability options.

Smart Integration: Incorporation of smart technologies, such as embedded sensors for monitoring structural health.