In modern industrial automation, where precise motion control and data transmission are essential, the Fanuc Encoder Cable 410IC is a high-performance cable designed to meet this need and is widely used in Fanuc robotic systems to ensure stable transmission of encoder signals and precise control of the robot.

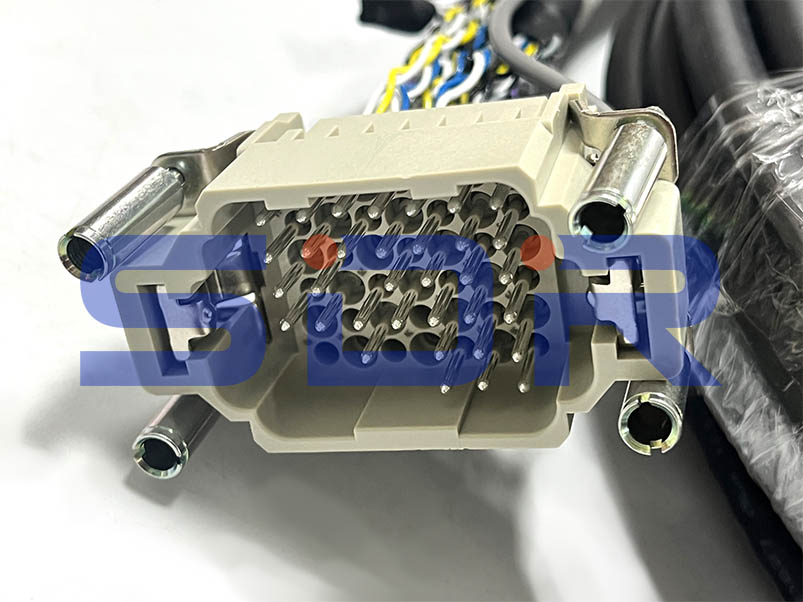

The Fanuc Encoder Cable 410IC is designed to connect the encoder of a Fanuc robot to the control system. It is responsible for transmitting the motion signals generated by the encoder to the robot controller, ensuring that the robot is able to accurately position itself and perform its intended tasks. The cable offers excellent durability and immunity to interference, enabling stable performance in demanding industrial environments.

Core Features

1. High durability: The Fanuc Encoder Cable 410IC is made of high-quality materials with excellent durability to withstand various stresses in industrial environments such as high temperatures, vibration, and mechanical friction.

2. Anti-interference ability: Designed with full consideration of electromagnetic interference (EMI), the cable is able to work stably in an environment with strong interference, ensuring the reliability of data transmission.

3. High-speed data transmission: The cable supports high-speed data transmission and can transmit encoder signals to the control system in real time, thus realizing precise motion control and position feedback.

4. Flexibility and Adaptability: The cable is designed to be flexible and adaptable to the needs of robots in different working postures, reducing performance problems caused by bending or twisting.

Application Areas

fanuc encoder Cable 410IC is widely used in industrial automation, precision manufacturing and high-precision machining. In these fields, the high performance of the cable ensures the stability and reliability of the robot system, thus improving productivity and product quality.

1. Industrial automation: In automated production lines, precise motion control is essential to ensure product consistency and productivity.

2. Precision Manufacturing: In manufacturing processes that require high-precision positioning, reliable encoder signal transmission is the basis for precise processing.

3. Test equipment: In a variety of test and measurement equipment, high-speed data transmission and accurate position feedback can improve the accuracy and efficiency of testing.

Installation and Maintenance

1. Installation: Installation of the Fanuc Encoder Cable 410IC needs to be carried out according to the specific robot model and application requirements. Proper access and securing is critical to avoid cable damage due to vibration or twisting.

2. Maintenance: Periodically check the integrity and connection status of the cable to ensure it is working properly. Regular maintenance helps prevent data transmission problems and ensures the long-term stability of the robot system.

The Fanuc Encoder Cable 410IC is an encoder cable that excels in demanding industrial environments. With its high durability, immunity to interference, and high-speed data transfer capability, it plays an important role in Fanuc robotic systems. Whether in industrial automation, precision manufacturing or test equipment, the cable provides reliable performance to ensure precise control and stable operation of robotic systems.