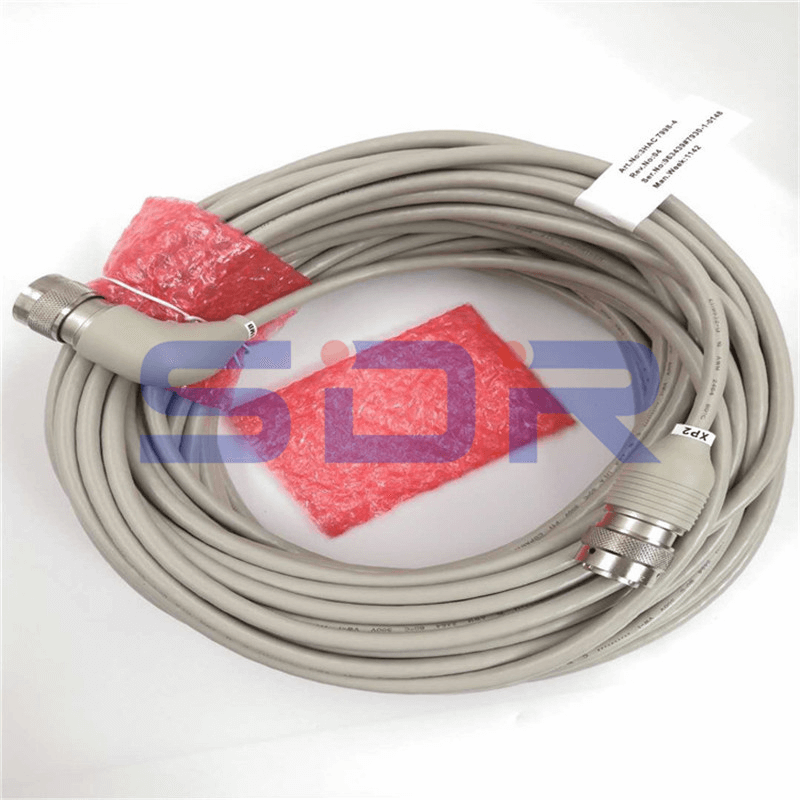

ABB Robot Encoder Cables are vital components in industrial robotics, ensuring precise transmission of position and speed data. Proper maintenance is essential to extend their operational life and maintain optimal performance. This guide outlines best practices for inspecting, cleaning, and storing ABB Encoder cables.

Regular inspection of Encoder Cables is crucial to identify wear and tear, physical damage, or signs of malfunction. Here’s how to inspect effectively:

Visual Examination:

Check for visible damage such as cuts, abrasions, or exposed wires.

Inspect connectors for bent pins, corrosion, or misalignment.

Flexibility Test:

Gently bend and flex the cable along its length to detect stiffness or cracks, which could indicate material fatigue.

Signal Performance Testing:

Use a multimeter or cable tester to ensure consistent electrical continuity and verify signal integrity.

Encoder cables can accumulate dust, oil, and debris in industrial environments. Cleaning them properly helps maintain efficiency and reduce the risk of interference.

Choose the Right Tools:

Use a soft, lint-free cloth or an anti-static brush to clean the surface.

For connectors, use isopropyl alcohol and cotton swabs to remove dirt.

Avoid Harsh Chemicals:

Do not use solvents or abrasive cleaners that can degrade insulation or shielding.

Cable Cover Cleaning:

If the cable has a protective sleeve, ensure it’s free of debris and securely fastened.

Proper storage prevents unnecessary wear and damage when cables are not in use.

Coil the Cable Correctly:

Use a loose coil to prevent kinks or sharp bends that can weaken the internal wiring.

Avoid over-tightening or forcing the cable into small loops.

Choose a Safe Environment:

Store cables in a dry, temperature-controlled area to prevent moisture buildup and material degradation.

Keep them away from direct sunlight, as UV rays can damage the insulation.

Protect Connectors:

Use protective caps or covers for connectors to shield them from dust and accidental damage.

Use Proper Cable Management:

Employ cable ties, sleeves, or conduits to secure cables and prevent tangling or pinching during operation.

Monitor Environmental Conditions:

Ensure the encoder cable is not exposed to excessive heat, chemicals, or physical stress.

Replace Worn-Out Cables Promptly:

If a cable shows significant signs of damage or performance degradation, replace it to avoid impacting the robot’s functionality.

Maintaining ABB Robot Encoder Cables involves regular inspection, thorough cleaning, and proper storage. By following these tips, you can extend the lifespan of your encoder cables, reduce downtime, and ensure the continued accuracy and efficiency of your ABB robotic systems. Proper care not only saves costs but also enhances the reliability of your automation setup.