In the realm of industrial automation, ABB (Asea Brown Boveri) has established itself as a leading provider of robotic solutions. ABB robots are renowned for their precision, productivity, and versatility. Behind the scenes, one critical component that ensures seamless robot performance is the cables that connect various components within the robotic system. In this article, we will explore the characteristics of ABB Robot Cables, highlighting their reliability, flexibility, and efficiency.

ABB Robot Cables are engineered to deliver exceptional reliability, enabling continuous and uninterrupted operation. These cables undergo rigorous testing and adhere to stringent quality standards, ensuring their ability to withstand the demanding conditions of industrial environments. With features such as robust insulation and shielding, ABB cables provide reliable signal transmission and power distribution, minimizing the risk of data loss, electrical interference, and downtime. Their durability ensures prolonged service life, reducing maintenance and replacement costs.

Flexibility is a key characteristic of ABB Robot Cables, allowing them to accommodate the complex and dynamic movements of robotic systems. The cables are designed with high flexibility in mind, enabling smooth articulation and unrestricted motion of robot arms and other moving components. ABB cables feature specialized materials and construction techniques that offer excellent flexibility without compromising their structural integrity. This flexibility enhances the overall performance of the robotic system by enabling precise and agile movements, improving productivity, and optimizing workspace utilization.

Efficiency is a paramount factor in industrial automation, and ABB Robot Cables are designed to contribute to overall system efficiency. These cables are engineered to minimize energy loss, ensuring efficient power transmission and distribution. By reducing energy waste, ABB cables promote cost savings and environmental sustainability. Additionally, ABB cables are lightweight and compact, optimizing space utilization within robotic systems. The streamlined design and efficient cable management solutions offered by ABB contribute to enhanced overall system performance and productivity.

ABB robot cables prioritize the protection and safety of both the robotic system and the operators. These cables incorporate advanced insulation and shielding technologies to safeguard against electrical hazards, including short circuits, electromagnetic interference (EMI), and electrostatic discharge (ESD). ABB cables are designed to meet stringent safety standards and are resistant to oil, chemicals, and harsh environmental conditions. This ensures reliable operation and minimizes the risk of damage to the cables or the surrounding equipment, enhancing overall workplace safety.

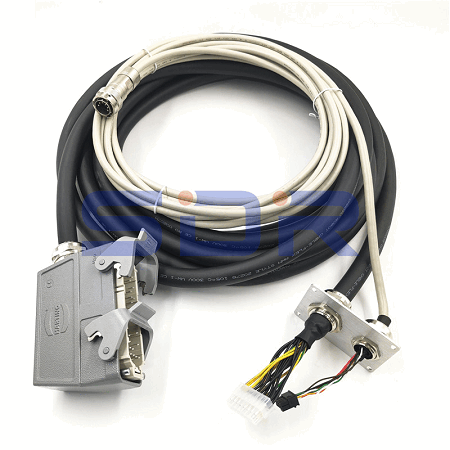

ABB recognizes the diverse needs of different robotic applications and offers a wide range of cables that can be customized to specific requirements. Whether it's a high-speed data transmission cable, a high-power cable, or a combination of both, ABB provides tailored solutions to ensure optimal performance. Furthermore, ABB cables are designed to be compatible with a variety of ABB robot models, facilitating seamless integration and ease of installation.

ABB robot cables are a crucial component of robotic systems, embodying the characteristics of reliability, flexibility, and efficiency. By ensuring uninterrupted performance, accommodating complex movements, promoting energy efficiency, and providing robust protection, ABB cables play a vital role in maximizing the productivity and safety of industrial automation. Their ability to be customized and their compatibility with various ABB robot models further enhances their value. When it comes to powering and connecting ABB robots, these cables serve as the lifeline, supporting smooth and efficient operation in diverse industrial applications.