In the realm of automation and robotics, ABB is a well-known and respected name. ABB robots have revolutionized industries by enhancing productivity, precision, and efficiency. One essential component of an ABB robot is the outer Axis Cable. In this article, we will delve into the functions and benefits of the ABB robot outer axis cable and understand its crucial role in ensuring seamless robot operation.

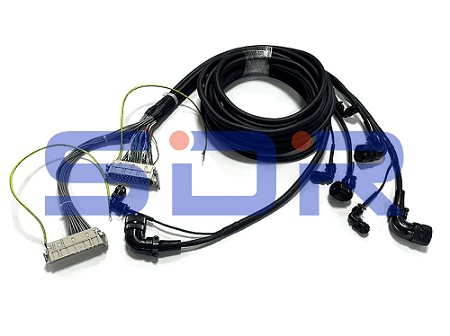

The outer axis cable is a specialized cable designed to connect and control the robot's external axis, such as a rotary arm, tool changer, or conveyor belt. It serves as the vital link between the Robot Controller and the external equipment, allowing for synchronized movement and precise control. The outer axis cable is engineered with high-quality materials, ensuring durability and resistance to harsh industrial environments.

Functions and Benefits:

1. Precise Signal Transmission:

The outer axis cable enables the accurate transmission of control signals from the robot controller to the external axis. It ensures that commands and movements dictated by the controller are executed flawlessly. This precision is vital in achieving accurate positioning, speed control, and synchronization, resulting in optimized production cycles and enhanced product quality.

2. Improved Flexibility and Maneuverability:

ABB robot outer axis cables are designed to be flexible and offer optimal maneuverability. This flexibility allows the robot and its associated external axis to navigate complex paths, reach various workstations, and adapt to different manufacturing scenarios. The Cables' design reduces the risk of tangling or restricting robot movement, ensuring consistent performance and preventing downtime.

3. Enhanced Safety Measures:

Safety is paramount in industrial robotic applications. The outer axis cable incorporates key safety measures to protect both the robot and the operator. It includes features such as shielding against electromagnetic interference and insulation to prevent electrical shocks or short circuits. These safety measures contribute to a secure working environment and minimize the potential for accidents or equipment damage.

4. Easy Installation and Maintenance:

ABB robot outer axis cables are designed with easy installation and maintenance in mind. They are often equipped with connectors and plugs that allow for quick and hassle-free attachment and removal. Additionally, the cables' robust construction reduces the risk of wear and tear, ensuring longevity and minimizing the need for frequent replacements or repairs.

5. Compatibility with ABB Robots:

ABB robot outer axis cables are specifically engineered to be compatible with ABB robots. This compatibility ensures seamless integration and optimized performance, as the cables are tailored to meet the unique requirements of ABB robot systems. It allows for efficient communication and coordination between the robot and its external axis, enabling accurate and synchronized movements.

The outer axis cable plays a crucial role in the smooth operation of ABB robots, allowing them to interact with and control external equipment accurately. With precise signal transmission, improved flexibility, enhanced safety, easy installation, and compatibility with ABB robots, these specialized cables empower industrial automation systems to perform complex tasks with efficiency and reliability. As technology advances, ABB continues to innovate and enhance its robot outer axis cables, meeting the ever-growing demands of industries and driving automation to new heights.