Fanuc Robots are widely used in various industries for their efficiency, precision, and versatility. As intricate machines, they require a complex system of cables to transmit signals and power to their different components. One crucial cable in a Fanuc robot is the outer Axis Cable. This essay aims to explore the function and significance of the Fanuc robot outer axis cable, shedding light on its role in facilitating robotic operations and enhancing overall performance.

The outer axis cable, also known as the servo POWER CABLE or motor power cable, is an integral part of the Fanuc robot's wiring system. It serves as a crucial medium for supplying electrical power from the controller to the robot's external axes, such as the wrist, arm, or tool. These external axes are responsible for precise movements and positioning, allowing the robot to carry out its designated tasks with accuracy and efficiency.

The primary function of the outer axis cable is to deliver electrical power from the Robot Controller to the different external axes. These axes, equipped with servo motors, require a reliable power source to operate effectively. The cable ensures a consistent supply of power, enabling the motors to drive the axes and move the robot arm smoothly and precisely. Without this power transmission, the robot's ability to perform complex tasks would be severely hindered.

In addition to power delivery, the outer axis cable also plays a vital role in facilitating control and communication between the robot controller and the external axes. It carries command signals, encoder feedback, and other critical data to ensure seamless coordination and synchronization between different robot components. By transmitting these signals accurately and in real-time, the cable allows for precise and responsive control, enabling the robot to execute intricate movements with high precision.

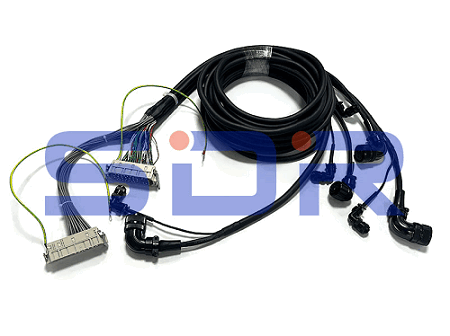

The outer axis cable is designed to withstand the demanding conditions of industrial environments. It is often subjected to intense vibrations, extreme temperatures, and exposure to chemicals or contaminants. Therefore, the cable is constructed using robust and durable materials, such as high-grade insulation and shielding, to ensure its longevity and reliable performance. Its protective features safeguard against potential electrical interference, minimizing the risk of data loss or system malfunctions.

Regular maintenance and inspection of the outer axis cable are crucial to ensure its optimal functionality and prevent potential issues. Industrial robots undergo constant movement and positioning, which can lead to cable wear and tear over time. Wear or damage to the outer axis cable can compromise power transmission, control signals, or even pose safety risks. Regular inspections, cable management practices, and prompt replacement of damaged cables are essential to maintain the robot's operational efficiency and ensure the safety of personnel working with the robot.

The Fanuc robot outer axis cable serves as a critical component in the robust and intricate wiring system of industrial robots. Its primary function of transmitting power and control signals to the external axes ensures the robot's accurate movement, positioning, and task execution. Furthermore, the cable's durability and protective features enhance its resilience to challenging operating conditions. By understanding the significance of the outer axis cable in maintaining robot performance and safety, technicians and operators can optimize its functionality through regular maintenance and ensure the sustained productivity of Fanuc robots in various industrial applications.