ABB (Asea Brown Boveri) is a leading global provider of industrial automation and robotic solutions. As an integral component of ABB's robot systems, cables play a crucial role in ensuring reliable and efficient communication, power transmission, and signal control. This essay aims to provide an in-depth examination of the various types of ABB Robot Cables, their characteristics, and applications.

1. Power Cables:

Power cables are responsible for delivering electrical energy from the power source to the robot. ABB offers a range of power cables designed to handle different voltage levels and power requirements. These cables are typically insulated with materials such as PVC (Polyvinyl Chloride) or XLPE (Cross-Linked Polyethylene) to ensure electrical safety. Power cables are crucial for supplying energy to drive motors, servos, and other power-consuming components within the robot.

2. Signal Cables:

Signal cables are vital for transmitting control signals between various components of the robot system. These cables carry commands, feedback, and sensor data, ensuring seamless communication and coordination among different parts of the robot. ABB's signal cables are shielded to minimize signal interference and maintain the integrity of transmitted data. High-quality signal cables are essential to ensure accurate control and feedback, enhancing the overall performance of the robotic system.

3. Ethernet Cables:

In an increasingly connected world, Ethernet cables play a pivotal role in facilitating network communication among robots, controllers, and peripheral devices. ABB offers Ethernet cables that comply with industry standards, providing fast and reliable data transfer rates. These cables enable real-time monitoring, programming, and diagnostics, enhancing the flexibility and functionality of ABB robot systems.

4. Motor Cables:

Motor cables are responsible for transmitting power and control signals between the robot's controller and motors. These cables need to handle high currents and withstand mechanical stresses associated with robotic movements. ABB's motor cables are designed with robust insulation materials to ensure durability, flexibility, and efficient power transmission. They also incorporate shielding to minimize electromagnetic interference and mitigate the risk of signal corruption.

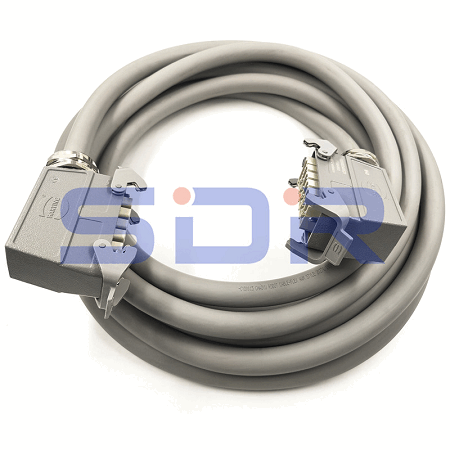

5. Dress Packs:

Dress packs consist of a combination of different cables, connectors, and conduits that are specifically organized and routed to ensure a neat and optimized cable management system within the robot. ABB provides dress pack solutions tailored to the specific robot models, ensuring efficient cable routing, reduced cable wear, and improved overall system performance. Dress packs also play a role in maintaining workplace safety by reducing the risk of cable snagging or entanglement.

ABB's range of Robot Cables is designed to meet the diverse requirements of industrial robotic systems. Power cables, signal cables, Ethernet cables, motor cables, and dress packs each serve distinct functions and contribute to the overall efficiency, reliability, and safety of ABB robot systems. By providing reliable power transmission, efficient signal control, seamless network connectivity, and optimal cable management, ABB Robot Cables enable robots to perform tasks with precision, accuracy, and productivity across a wide range of industries. As ABB continues to innovate in the field of industrial automation, its Robot Cables will undoubtedly continue to play a significant role in shaping the future of robotics.