In the realm of automation and robotics, ABB is a renowned name, delivering cutting-edge solutions that enhance efficiency, precision, and productivity. Among its vast array of offerings, ABB Robot Encoder Cables hold a crucial role in ensuring seamless communication between the robot's encoder and the control system. This essay aims to delve into the significance of ABB Robot Encoder Cables and elucidate the reasons why their integration is indispensable.

ABB Robot Encoder Cables serve as the vital link between the robot's encoder and the control system, enabling the transmission of critical data. Encoders play a pivotal role in measuring position, velocity, and angular displacement, providing real-time feedback for precise control. The encoders produce digital signals that need to be accurately conveyed to the control system without interference or data loss. Encoder cables, designed specifically for ABB robots, ensure reliable data transmission, maintaining the fidelity of information and facilitating smooth operational performance.

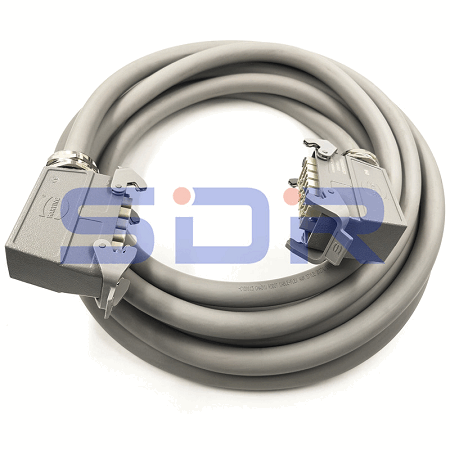

ABB Robot Encoder Cables are engineered to withstand the demanding industrial environment, which includes exposure to harsh temperatures, vibrations, and mechanical stress. These cables are constructed using high-quality materials and advanced shielding techniques, ensuring durability and longevity. The robust design safeguards against signal degradation, electrical noise, and external interference, thereby maintaining the integrity of the transmitted data. Additionally, the cables' protective insulation prevents damage due to mechanical strain, ensuring uninterrupted functionality even in challenging operating conditions.

Precise and accurate motion control is imperative in industrial applications, particularly in robotics. ABB Robot Encoder Cables contribute significantly to achieving enhanced precision and accuracy in robotic systems. By facilitating the seamless transmission of encoder signals, these cables enable the control system to precisely monitor and adjust the robot's position and movement. This level of precision is crucial in industries such as manufacturing, where even the slightest deviation can have significant consequences. Thus, the integration of ABB Robot Encoder Cables plays a vital role in optimizing process performance and ensuring consistent high-quality output.

Efficiency and productivity are paramount considerations for any industrial operation. ABB Robot Encoder Cables directly contribute to these aspects by reducing downtime, minimizing errors, and optimizing the overall operational workflow. An uninterrupted and secure data transmission ensures minimal system disruptions and aids in swift fault identification and troubleshooting. By maintaining reliable communication between the robot's encoder and the control system, these cables help prevent costly errors, streamline operation, and maximize productivity.

ABB Robot Encoder Cables are specifically designed to seamlessly integrate with ABB robotic systems, allowing for easy installation and compatibility. ABB's expertise in automation and robotics ensures that these cables are meticulously engineered to meet the requirements of their robot models, guaranteeing plug-and-play functionality. The streamlined integration enhances the overall system performance, reducing setup time and effort while ensuring optimal performance.

In conclusion, the integration of ABB Robot Encoder Cables is vital in maintaining reliable communication between the robot's encoder and the control system. These cables play a crucial role in transmitting critical data accurately, ensuring robustness in demanding industrial environments, enhancing precision and accuracy, improving productivity, and enabling seamless integration with ABB robotics solutions. By understanding the significance of ABB Robot Encoder Cables, industries can harness their power to unlock new possibilities in automation and achieve operational excellence.