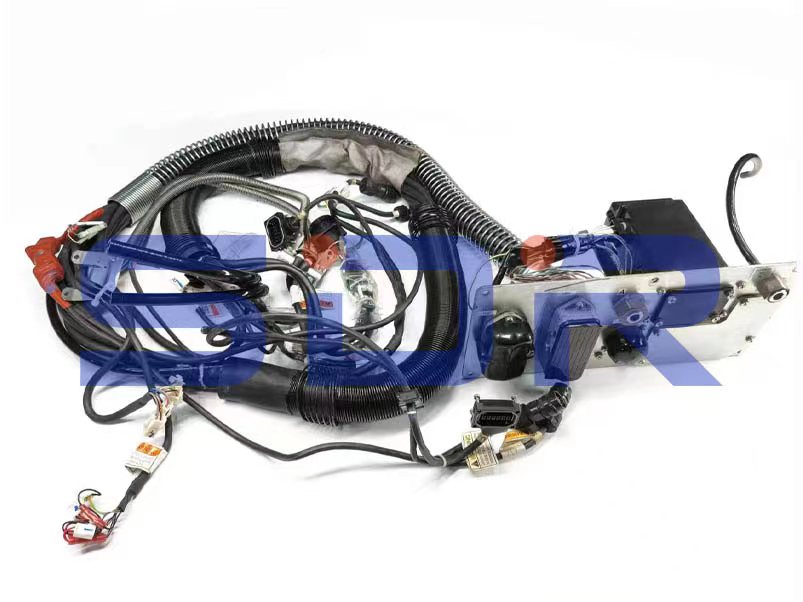

Yaskawa Robot 1-6 Axis Body Cable DX200 MA2010

Yaskawa Robot 1-6 Axis Body Cable has excellent mechanical strength and wear resistance, and has good contact and Anti-shake ability to ensure the reliability and stability of data transmission.

Features

1. High reliability: The cable DX200 MA2010 is made of high-quality materials, and has undergone multiple tests and strict quality control to ensure its stability and reliability. The cable connector part is made of high-quality metal materials, and a special protection device is added, which can support the long-term, high-speed and high-frequency movement of the robot, ensure the precise and smooth linkage of each axis of the robot, and improve production efficiency.

2. Safety: It adopts green and environmental protection materials that meet the RoHS standard, which is safe and reliable, and meets the electrical safety requirements of international standards.

3. Durability: The fuselage cable DX200 MA2010 has been processed by a special process, which has good protection performance, wear resistance and corrosion resistance, which helps to prolong the service life and reduce the maintenance and replacement costs of the robot.

4. Easy to install: The DX200 MA2010 connector of the 1-6 axis body cable of the robot adopts a plug-in design, which is easy to install and disassemble, and can effectively save installation costs and time.

Product Specifications

Brand: | Yaskawa |

Jacket: | PVC or PUR |

Core Material: | Bare Copper conductor |

Length: | As custom |

Product No.: | DX200 MA2010 |

Applications: | Yaskawa Industrial Robot |

Key Features

Highly Flexible Design: Yaskawa's Robotic cables offer superior flexibility to withstand frequent bending and twisting. This is critical for the operation of multi-axis robots, which are required to perform a variety of delicate movements in complex environments.

Durability and Reliability: The cables are made of high-strength materials with excellent abrasion resistance and tensile strength, enabling long-term use in harsh industrial environments without damage.

Efficient Data Transmission: Yaskawa's cable design focuses on the stability and efficiency of signal transmission, ensuring uninterrupted data transmission during high-speed operations. This is critical for robot systems that require precise control and real-time feedback.

High level of protection: The cables are well protected against water, dust and oil, making them suitable for use in a wide range of harsh operating environments, further improving the reliability and service life of the equipment.

Application Areas

Yaskawa Cable Robot 1-6 Axis Body Cable is widely used in the following fields:

Manufacturing: In automated production lines, for connecting and controlling robots for efficient production and assembly operations.

Automotive industry: for welding, assembly and painting of automotive parts to ensure high precision and efficiency in the production process.

Electronics industry: Robotic cables are used for high-precision handling and assembly tasks in the manufacturing of precision electronic equipment.

Food and beverage industry: In the processing and packaging of food and beverages, the cables ensure stable operation and high efficiency of the robots.

Installation and Maintenance

Yaskawa Cable Robot 1-6 Axis Body Cable is also relatively easy to install and maintain:

Installation guide: Yaskawa provides a detailed installation guide and technical support to help users quickly install and configure the cable.

Periodic Inspection: It is recommended that the cable be inspected periodically, especially in high frequency operations and harsh environments, to ensure that the cable is not frayed or damaged.

Professional maintenance: When problems are found, contact professional technicians for maintenance and replacement in time to avoid affecting the normal operation of the robot system.

FAQ:

What is the main function of the Yaskawa Cable Robot 1-6 Axis Body Cable?

The main function of the Yaskawa Cable Robot 1-6 Axis Body Cable is to connect the axes of the Yaskawa robot to ensure stability and reliability of data transmission and power supply.

What are the design features of this cable?

The cable has a highly flexible design that can withstand frequent bending and twisting, as well as durability and efficient data transmission for use in harsh industrial environments.

What is the application of Yaskawa Cable Robot 1-6 Axis Body Cable in manufacturing?

In manufacturing, this cable is used to connect and control robots for efficient production and assembly operations.

Why is this cable popular in the automotive industry?

Because it is used in processes such as welding, assembly and painting of automotive components to ensure high precision and efficiency in the production process.

How protective is this cable?

Yaskawa's cables are well protected against water, dust and oil, and are suitable for use in a variety of harsh operating environments.

What are the recommendations for installation and maintenance of the cable?

When installing the cable, you should refer to the installation guide and technical support provided by Yaskawa, check the cable regularly, and contact a professional technician for maintenance and replacement when problems are found.

What is the specific use of Yaskawa Cable Robot 1-6 Axis Body Cable in the electronics industry?

In the electronics industry, the cable is used for high-precision handling and assembly tasks to ensure that the manufacturing process of precision electronic equipment is efficient and accurate.

What is the role of this cable in the food and beverage industry?

In the processing and packaging of food and beverages, the cable ensures stable operation and efficient work of robots.

What is the durability of Yaskawa cables?

Yaskawa cables are made of high-strength materials with good abrasion resistance and tensile strength, enabling long-term use in harsh industrial environments without damage.

What is the importance of efficient data transmission for Yaskawa Cable Robot 1-6 Axis Body Cable?

Efficient data transfer ensures uninterrupted data transmission during high-speed robot operation, which is critical for robot systems that require precise control and real-time feedback.